Data Analytics Simplifying Workflows

For E&P Operators during Well construction

Data Analytics Simplifying Workflows

For E&P Operators during Well construction

15 Plus years of Drilling Data Analytics Experience

For over 15 years, harnessing the power of data to help Oil & Gas Operators to improve performance by reducing drilling costs and reducing drilling risks.

15 years

Trusted By

Client Testimonials

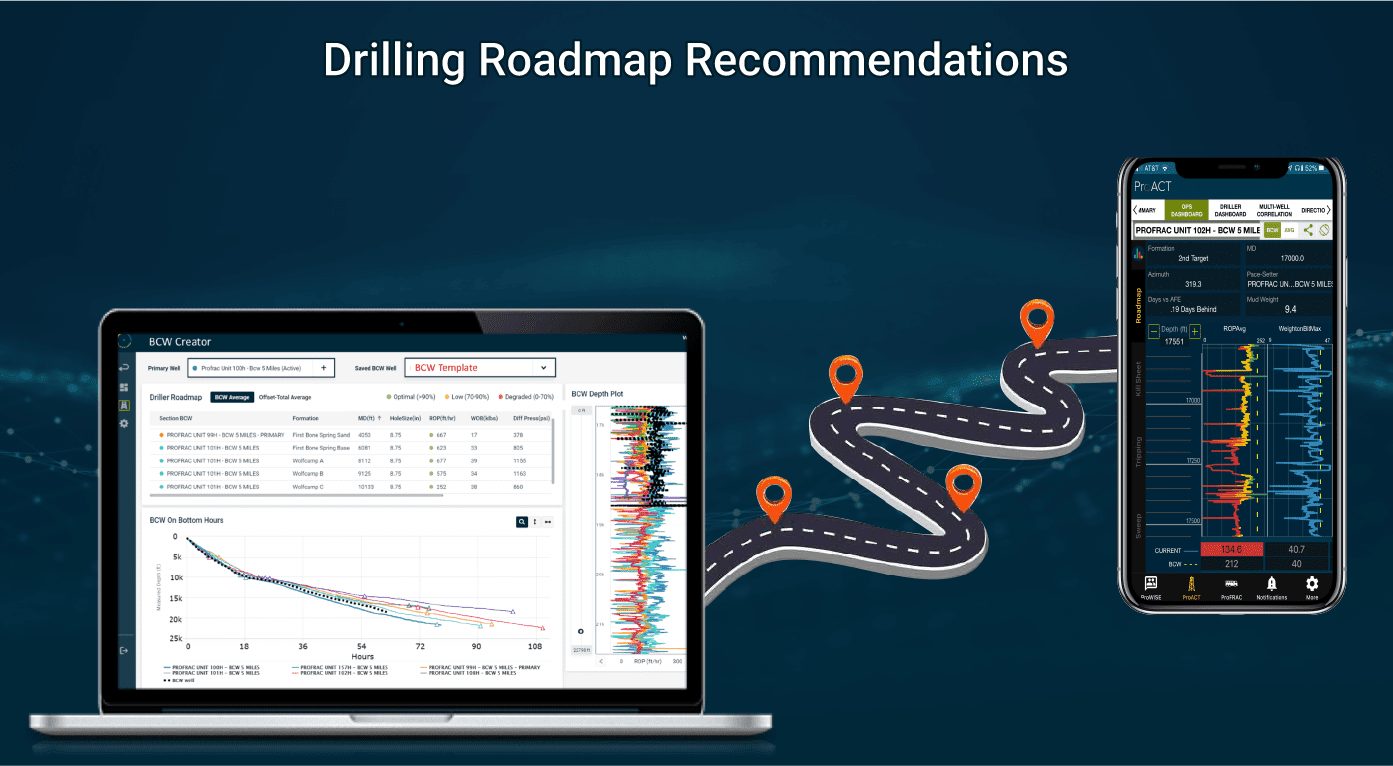

View our Drilling Data Analytics Platform

Simplifying Workflows for all stakeholders during all phases of Well Construction by harnessing the power of data